Pipe Thread Dimensions⁚ A Comprehensive Guide

This comprehensive guide will delve into the intricacies of pipe thread dimensions, providing a detailed understanding of their different types, sizes, and applications. We will explore the most common pipe thread standards, such as NPT (National Pipe Taper) and BSP (British Standard Pipe), and their respective dimensions. This guide will also furnish you with the knowledge to select the appropriate pipe thread for your specific requirements.

Introduction

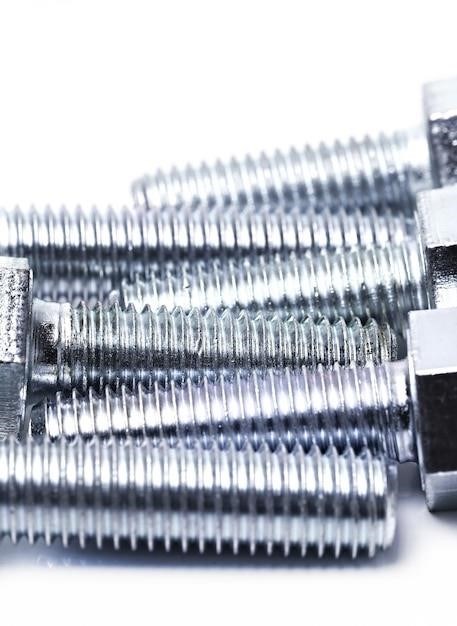

In the world of plumbing, industrial equipment, and various mechanical systems, understanding pipe thread dimensions is paramount. Pipe threads are essential for creating secure, leak-proof connections between pipes, fittings, and valves. These threads are not simply decorative; they serve a crucial role in ensuring the proper functioning and longevity of various systems. However, navigating the complexities of pipe thread dimensions can be daunting, especially for those unfamiliar with the terminology and standards. This guide aims to demystify the world of pipe thread dimensions, providing a comprehensive overview of the different types, sizes, and applications.

We will explore the fundamental concepts of pipe thread sizes, delving into the intricacies of the National Pipe Taper (NPT) standard, which is widely used in North America. You will learn about the different NPT thread sizes, their corresponding dimensions, and how to calculate them. We will also discuss the application of NPT threads in various industries, highlighting their importance in plumbing, construction, and industrial settings.

Furthermore, we will delve into other prevalent pipe thread standards, such as the British Standard Pipe (BSP) and the Metric pipe thread. Understanding these standards is crucial for ensuring compatibility and proper connection between different components. Finally, we will provide practical guidance on choosing the right pipe thread for your specific needs, considering factors such as the intended application, materials, and pressure requirements.

By the end of this guide, you will have a solid understanding of pipe thread dimensions and the knowledge to confidently select and utilize the appropriate threads for your projects. This comprehensive overview will equip you with the tools to ensure secure, leak-free connections and optimal performance in your plumbing, industrial, and mechanical applications.

Understanding Pipe Thread Sizes

Pipe thread sizes might seem confusing at first glance. They are not directly related to standard units of measurement like inches or millimeters. Instead, they are considered nominal sizes, meaning they are roughly based on the inside diameter (ID) of the pipe. For instance, a 1/2-inch pipe thread does not have an actual outside diameter of 1/2 inch.

The nominal size is primarily related to the inside diameter of the Schedule 40 pipe series, which is a common pipe thickness standard. This means a 1/2-inch pipe thread will typically fit a pipe with an inside diameter close to 1/2 inch. However, the actual thread dimensions, including the outside diameter, pitch, and taper, can vary depending on the thread standard used.

It’s crucial to understand that pipe thread sizes are not interchangeable across different standards. Using the wrong type of pipe thread can lead to compatibility issues, leaks, and even damage to equipment. Therefore, carefully identifying the specific pipe thread standard and its corresponding dimensions is essential for ensuring proper installations and maintenance.

This guide will provide a clear explanation of the different pipe thread standards, including their unique characteristics and dimensions. We will also explore the factors that influence the choice of pipe thread, such as pressure requirements, material compatibility, and industry standards. This knowledge will empower you to select the right pipe thread for your specific applications, ensuring safe, reliable, and leak-free connections.

NPT (National Pipe Taper) Thread Dimensions

NPT (National Pipe Taper) threads are the most prevalent pipe thread standard in the United States and are characterized by their tapered design. This taper ensures a tight seal when the male and female threads are engaged, preventing leaks and maintaining system integrity.

The taper rate for all NPT threads is 1/16 inch per inch of length (3/4 inch per foot), meaning the diameter of the thread increases by 1/16 inch for every inch of thread length. This taper is crucial for creating a pressure-tight seal as the male thread is tightened into the female thread. The angle between the taper and the center axis of the pipe is 1° 47′ 24″ (1.7899°).

Each NPT thread size has a defined number of threads per inch (TPI), which determines the pitch of the thread. For instance, a 3/4 NPT pipe thread has 14 threads per inch. The outside diameter (OD) of an NPT thread is also specific to each size, and it is typically larger than the nominal pipe size. For example, a 3/4 NPT pipe thread has an outside diameter of 1.050 inches.

The basic maximum thread height, “h,” of the truncated thread is 0.8 times the pitch of the thread. The crest and root of the thread are truncated to ensure proper engagement and prevent damage. The truncation depth is a minimum of 0.15 times the pitch of the thread. These dimensions and tolerances are critical for ensuring compatibility and a secure seal.

Understanding NPT thread dimensions is essential for engineers, technicians, and anyone working with pipe systems in the United States. This knowledge enables them to choose the correct fittings, ensure proper installation, and maintain the integrity of pipe systems.

NPT Thread Dimensions Chart

A comprehensive NPT thread dimensions chart is a valuable resource for anyone working with pipe systems. It provides a clear and concise overview of the various NPT thread sizes and their corresponding dimensions. The chart typically includes the following information⁚

• Nominal Pipe Size (NPS)⁚ This represents the approximate inside diameter (ID) of the pipe, though it does not directly correspond to the actual thread dimensions.

• Threads Per Inch (TPI)⁚ This value indicates the number of threads per inch of length, determining the pitch of the thread.

• Outside Diameter (OD)⁚ This refers to the diameter of the male thread at the crest, which is larger than the nominal pipe size.

• Pitch Diameter⁚ The pitch diameter is the average diameter of the thread, measured halfway between the crest and the root.

• Major Diameter⁚ The major diameter is the largest diameter of the thread, measured at the crest.

• Minor Diameter⁚ The minor diameter is the smallest diameter of the thread, measured at the root.

• Thread Depth⁚ The thread depth is the distance between the crest and the root.

• Taper Rate⁚ The taper rate is the change in diameter per unit length, which is 1/16 inch per inch for all NPT threads.

Having access to a readily available NPT thread dimensions chart simplifies the selection of appropriate fittings, ensures proper installation, and helps avoid costly mistakes. These charts can be found in various engineering handbooks, online resources, and manufacturer catalogs.

Calculating NPT Thread Dimensions

While NPT thread dimensions charts provide readily accessible information, understanding how to calculate them can be beneficial for various applications. This knowledge is particularly useful when dealing with non-standard sizes or when precise measurements are crucial.

The calculation of NPT thread dimensions involves a few key factors⁚

• Nominal Pipe Size (NPS)⁚ The NPS is the starting point, providing a general indication of the thread’s size.

• Threads Per Inch (TPI)⁚ Each NPT thread size has a defined TPI value, which dictates the pitch of the thread.

• Taper Rate⁚ The taper rate of NPT threads is constant at 1/16 inch per inch, meaning the diameter changes by 1/16 inch for every inch of thread length;

To calculate the outside diameter (OD) of an NPT thread, you can use the following formula⁚

OD = NPS + (Taper Rate x Length of Thread)

For example, to calculate the OD of a 1/2 inch NPT thread with a length of 1 inch⁚

OD = 1/2 + (1/16 x 1) = 0.5625 inches

The pitch diameter can be calculated using the formula⁚

Pitch Diameter = OD ⎻ (Thread Depth / 2)

Where the thread depth is determined by the TPI value.

These formulas provide a basic understanding of how to calculate NPT thread dimensions. However, it’s important to note that these are simplified calculations and may not account for all tolerances and variations. For precise measurements and critical applications, refer to industry standards and manufacturer specifications.

Common Applications of NPT Threads

NPT threads, due to their robust design and widespread adoption, find application in a wide range of industries and applications. Their inherent ability to create a tight seal, even under pressure, makes them suitable for various fluid handling systems. Here are some prominent applications of NPT threads⁚

• Plumbing and Piping⁚ NPT threads are prevalent in plumbing systems, connecting pipes, fittings, and fixtures for water, gas, and drainage. Their tapered design creates a tight seal, preventing leaks and ensuring reliable operation.

• Industrial Equipment⁚ In industrial settings, NPT threads are commonly used in machinery, equipment, and processes involving fluid handling, such as hydraulic systems, pneumatic systems, and chemical processing.

• Automotive⁚ NPT threads are found in various automotive applications, including fuel lines, oil lines, and coolant lines. Their ability to withstand pressure and vibration makes them suitable for these critical systems.

• Aerospace⁚ While less common than in other industries, NPT threads can be found in aerospace applications, particularly in ground support equipment and auxiliary systems.

• Medical Devices⁚ NPT threads find use in medical devices and equipment, particularly in fluid handling systems and components. The tight seals they provide are crucial for maintaining sterility and preventing contamination.

• Construction⁚ In construction, NPT threads are used in various applications, including connecting pipes for water, gas, and drainage systems in buildings and infrastructure projects.

The versatility and reliability of NPT threads have made them a staple in a wide range of industries, ensuring efficient and secure fluid handling in diverse applications.

Other Pipe Thread Standards

While NPT (National Pipe Taper) threads are widely used, especially in North America, other pipe thread standards exist, catering to specific needs and geographical preferences. These standards differ in thread profiles, dimensions, and applications, ensuring compatibility within their respective regions and industries. Let’s explore some prominent pipe thread standards besides NPT⁚

• British Standard Pipe Thread (BSP)⁚ BSP threads are widely used in the United Kingdom, Commonwealth countries, and many parts of Europe. They are characterized by a parallel thread profile, meaning the thread diameter remains constant along the length of the thread. BSP threads are commonly used in plumbing, hydraulics, and general engineering applications.

• Metric Pipe Thread (MPT)⁚ MPT threads are based on the metric system, making them widely used in continental Europe and other regions adopting the metric standard. MPT threads are typically parallel, but they also come in tapered versions. They are frequently used in plumbing, hydraulics, and industrial applications.

• Japanese Industrial Standard (JIS)⁚ JIS threads are a standard developed in Japan, commonly used in Japanese industries and products. JIS threads are typically parallel and follow metric dimensions. They are prevalent in plumbing, hydraulics, and industrial applications in Japan and regions with strong ties to Japanese industry.

• American National Standard (ANSI)⁚ While not as widely used as NPT, ANSI threads are prevalent in certain industrial applications. They offer a parallel thread profile and are often used for specialized components and equipment.

Understanding these different pipe thread standards is essential for ensuring compatibility and selecting the right threading for your specific applications, whether it’s plumbing, industrial machinery, or automotive systems. Always refer to the applicable standard for the specific thread dimensions and specifications.

British Standard Pipe Thread (BSP)

British Standard Pipe Thread (BSP) is a widely recognized pipe thread standard used primarily in the United Kingdom, Commonwealth countries, and many parts of Europe. It stands out from NPT (National Pipe Taper) by employing a parallel thread profile, meaning the thread diameter remains constant along the entire length of the thread. This contrasts with NPT’s tapered profile, which gradually decreases in diameter. The consistent thread diameter in BSP threads simplifies sealing, as a consistent pressure is applied across the entire sealing surface.

BSP threads are further categorized into two primary types⁚ BSPP (British Standard Pipe Parallel) and BSPF (British Standard Pipe Taper). BSPP threads are parallel, while BSPF threads feature a slight taper. BSPP threads are commonly used in plumbing, hydraulics, and general engineering applications, while BSPF threads are often employed in applications requiring a more secure seal, such as high-pressure systems.

BSP threads are defined by their nominal size, which is typically expressed in fractions of an inch. For instance, a 1/2″ BSP thread has a nominal size of 1/2 inch. The actual dimensions of the thread, however, are not directly related to the nominal size. To ensure accurate measurements, it is crucial to refer to a BSP thread dimension chart or a comprehensive resource like a pipe thread dimensions PDF. This will provide detailed information on the thread diameter, pitch, and other crucial parameters for each BSP thread size.

When working with BSP threads, it is essential to use the appropriate tools and ensure compatibility with the relevant standards. Using the wrong tools or incompatible components can lead to leaks, damage, and potentially hazardous situations. By understanding the intricacies of BSP threads and adhering to established standards, you can ensure efficient and reliable connections in your plumbing, hydraulic, and engineering applications.

Metric Pipe Thread

Metric Pipe Thread (MPT) is a standardized thread system that utilizes metric units for its dimensions. It is gaining popularity globally, particularly in applications where metric measurements are favored. Unlike NPT (National Pipe Taper) and BSP (British Standard Pipe), which use fractional inch measurements, MPT employs millimeters for its thread diameter and pitch. This ensures consistency with other metric components and simplifies calculations.

MPT threads are typically designated by their nominal size followed by the letter “M” and then the thread pitch. For instance, a thread with a nominal size of 20 millimeters and a pitch of 1.5 millimeters would be denoted as “M20x1.5.” The nominal size generally corresponds to the approximate internal diameter of the pipe, but it’s important to consult a metric pipe thread dimension chart for precise measurements.

MPT threads are available in both parallel and tapered profiles. Parallel MPT threads, often referred to as “straight threads,” maintain a constant diameter along their entire length. They are commonly used for plumbing and general applications requiring a consistent pressure distribution across the sealing surface. Tapered MPT threads, sometimes called “taper threads,” have a gradual reduction in diameter along the thread. These threads are typically used in applications where a tighter seal is required, such as high-pressure systems.

To ensure accurate measurements and proper mating of components, it is crucial to refer to a comprehensive metric pipe thread dimension chart or a detailed pipe thread dimensions PDF. These resources will provide specific dimensions for each MPT thread size, including thread diameter, pitch, and other critical parameters. This information is essential for selecting the correct tools and ensuring compatibility between components, ultimately contributing to leak-free and reliable connections.